Micro Laser Welding

There micro-welding it can be achieved by means of two different techniques.

Micro Laser Welding: the advantages

Micro Laser Welding: the advantages

NTsaldature has invested precisely in this sector and is equipped with two very high precision implants, offers interventions for the repair of tools and molds.

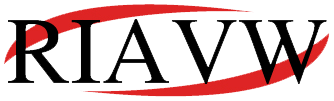

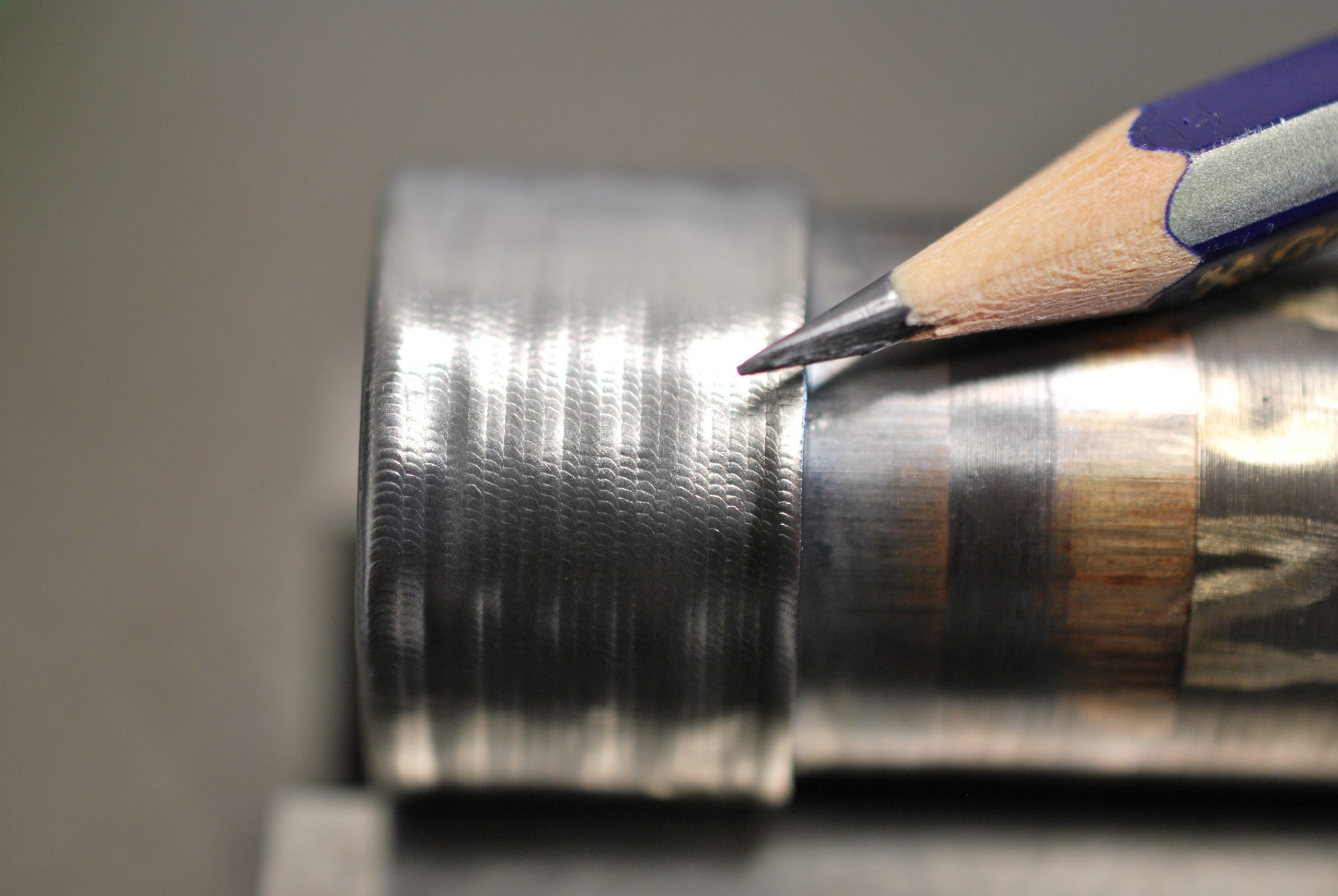

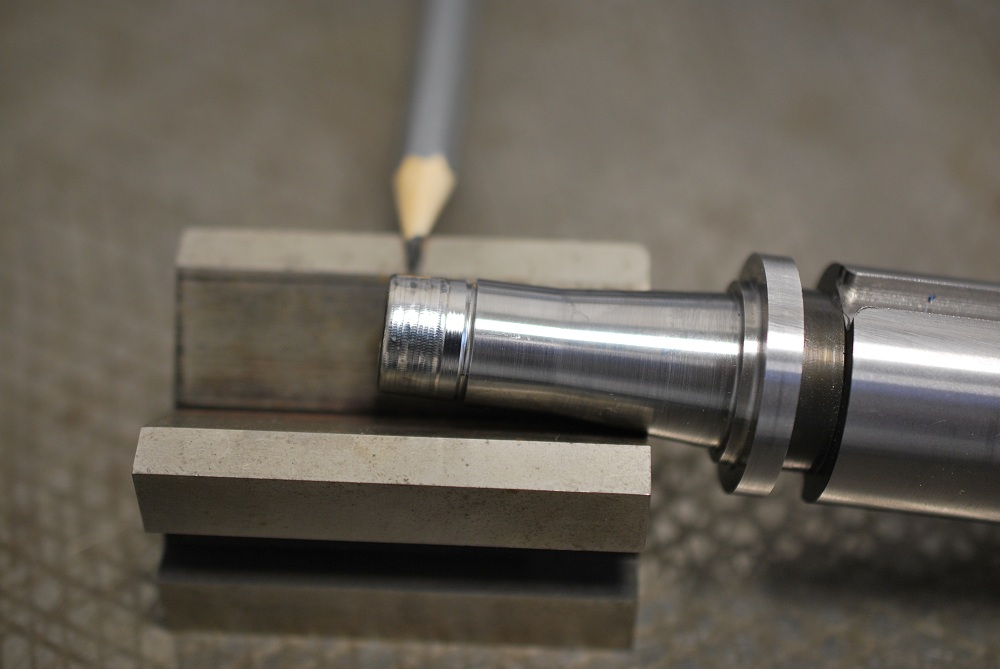

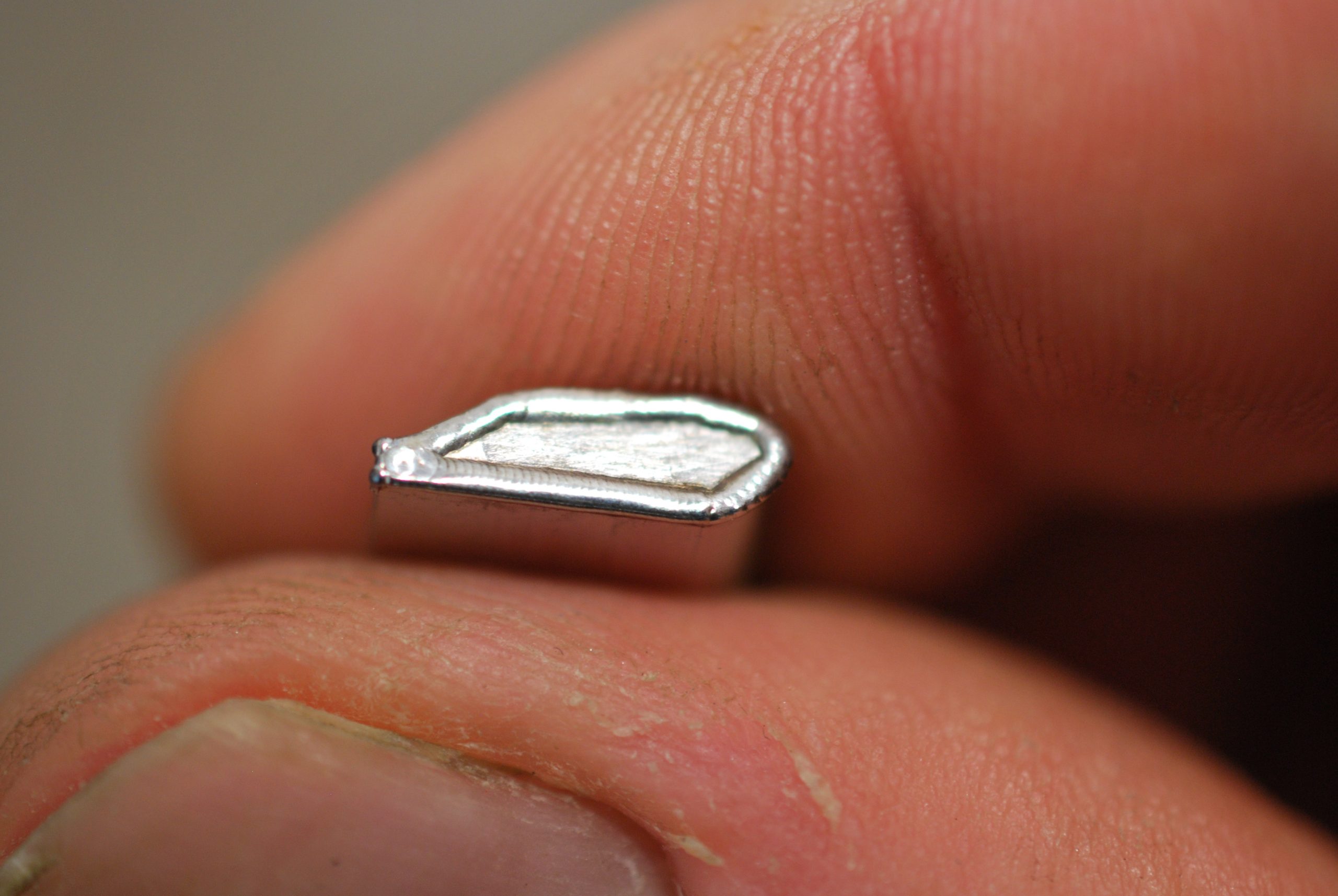

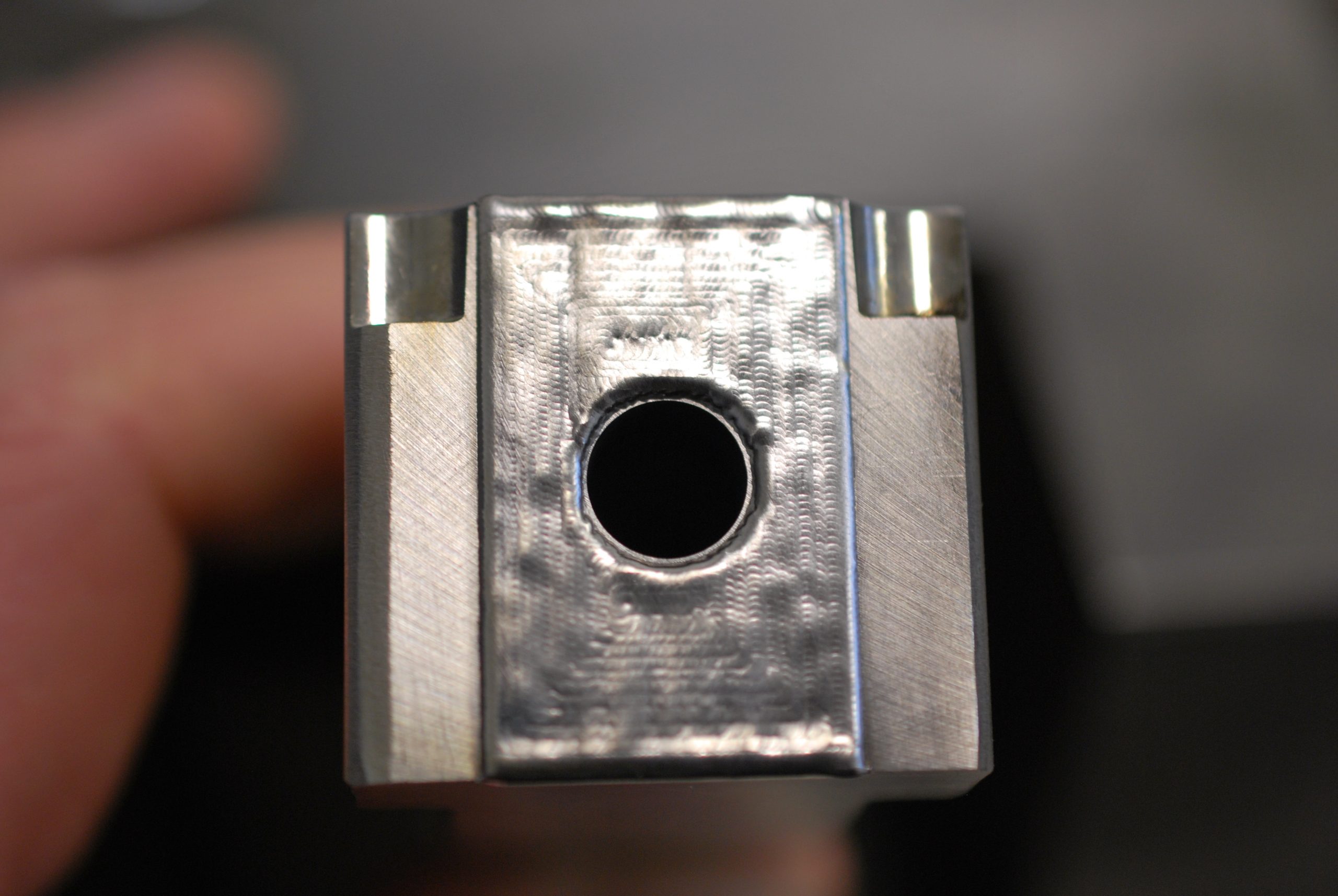

The high level of processing and the use of a microscope with a cutting-edge lens system, allows to carry out coatings, even of a few hundredths of mm (0.06), on all kinds of shapes, from the most linear to the extremely complex; the accessories of the welder then allow micro-welding to be carried out even in hardly accessible points.

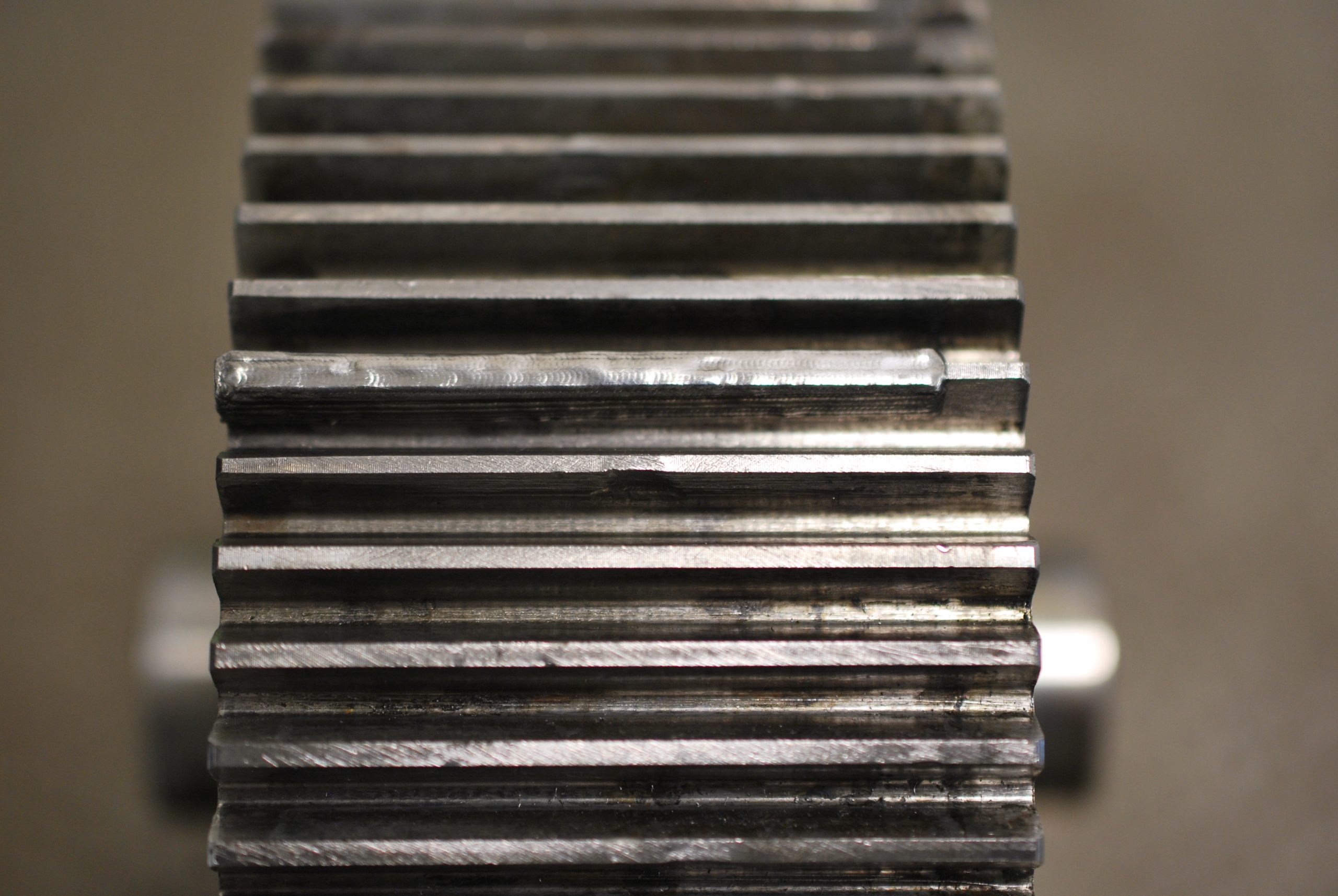

A further advantage of this welding process consists in thetotal elimination of the risk of distortion detail and alteration of materials. Precisely in the context of the peculiarities of the metal to be welded, it is good to take into account the fact that laser welding, guided by the experience of the person performing it, allows to obtain metal coatings of various hardnesses; in fact, according to the metal selected for the supply of material, a degree of hardness equal to or greater than 60 HRC can be reached.

Each intervention that must be carried out is therefore carefully evaluated a priori, so that it is carried out using the most appropriate technique, in accordance with the customer's needs.

Micro Laser Welding when to use it:

The laser welding process is purely used when there is the need to carry out coatings with a very high degree of precision, obtaining excellent penetration qualities or when a standardized process is required.

It is a process that is often used for joining very thin-thickness materials that could not be welded by other techniques, due to the high risk of distortion.

Micro Laser Welding fields of application:

This process has different fields of application: from the repair of molds for plastic materials, for shearing, cold, etc ..., to interventions that require the union of various types of metals including titanium, aluminum alloys, copper, cast iron, stainless steel, etc ..., to the maintenance of any metal object.

The laser technique also allows to carry out coatings in deep areas, such as hollows, holes, channels, etc… impossible to reach by means of other welding technologies.

There are no reviews yet.