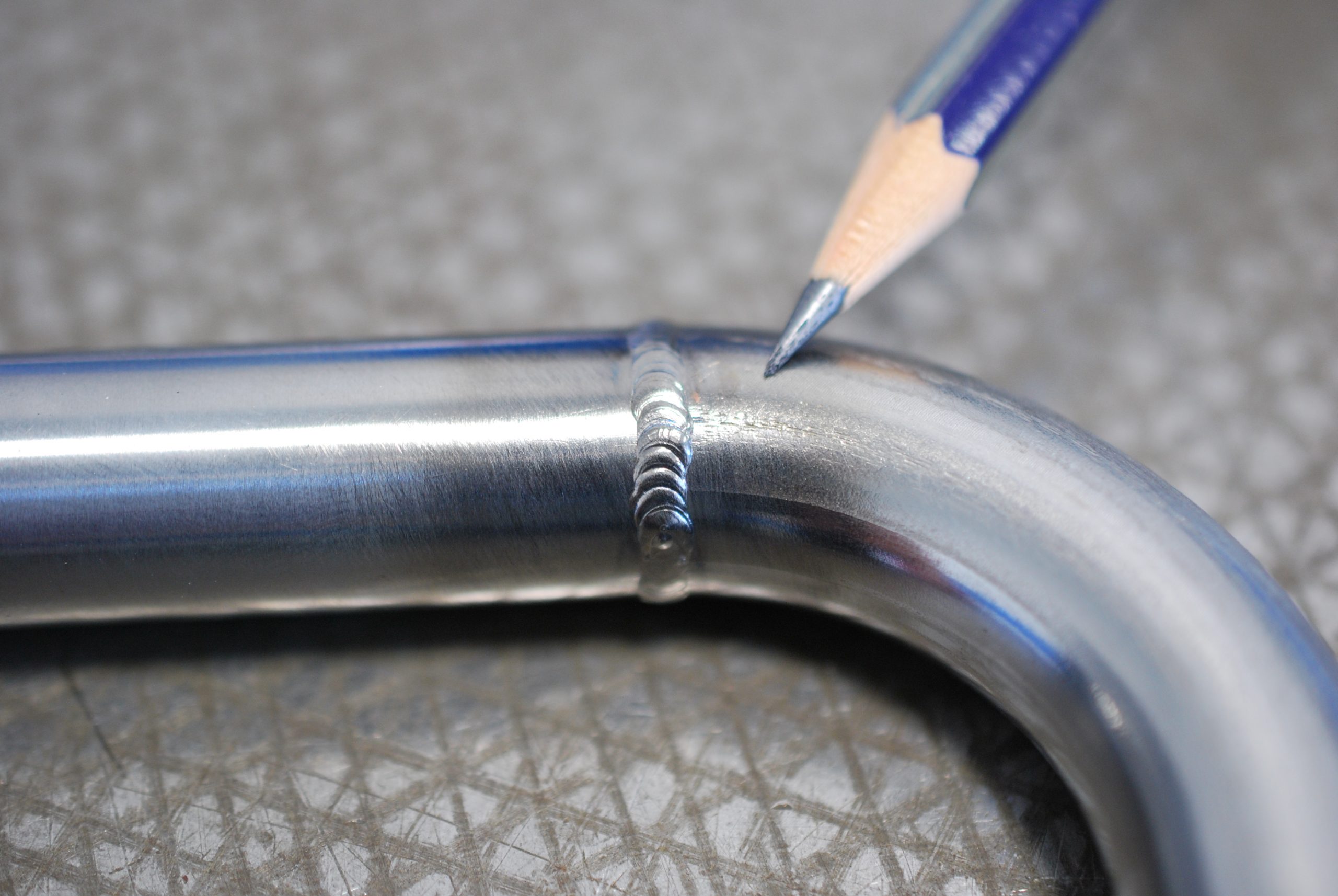

Micro Tig welding: the advantages

The micro TIG process allows to carry out localized micro coatings using wires even of DN 0.3 mm without encountering excessive overheating capable of compromising, not only the geometry of the part, but also its mechanical characteristics.

It also guarantees excellent quality, as, by generating a fusion, any impurities tend to come to the surface, and then be expelled (vaporized).

Since these are micro carryovers, even the area adjacent to the weld (HAZ, thermally altered area) is very limited, therefore the micro TIG guarantees a more targeted intervention in this sense.

Micro Tig welding: when to use it

A high percentage of our customers ask us to carry out coatings using laser sources, ignoring however that, for some applications, micro TIG is the best compromise.

The experience gained in 30 years of activity has led us to perform various tests following which it emerged that, in order to be complete at 360 °, we would have had to invest not only in traditional processes, but also in lightly traveled terrain.

This procedure presupposes the acquisition of theoretical and practical skills that only well-trained workers possess; these skills, in recent years, have brought NTsaldature many satisfactions.

The technical excellence of our staff has allowed us to perform highly complex interventions, thanks to these operational skills.

There are no reviews yet.