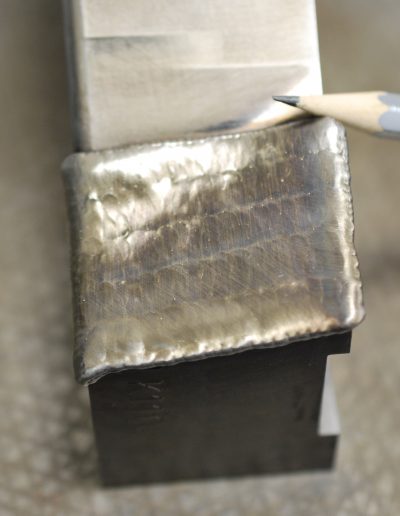

Tig welding

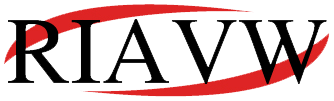

TIG (Tungsten Inert Gas) welding is a process that uses the arc produced by an infusible electrode.

Tig welding: the advantages

Tig welding: the advantages

It is a very functional process for joining metal parts of various shapes and sizes.

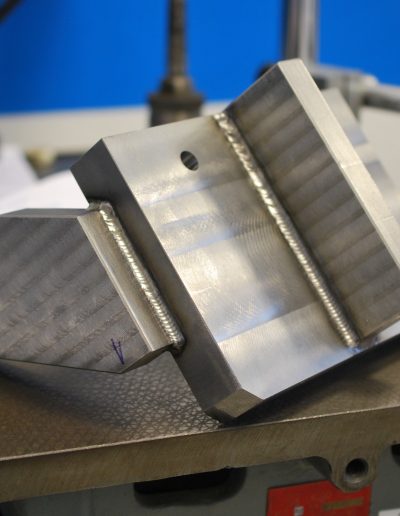

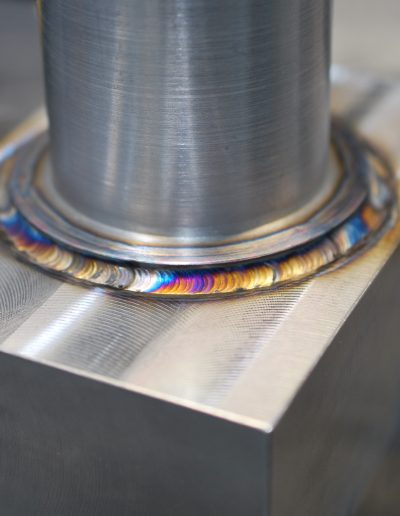

In recent years there has been such an evolution of welding generators, as to allow machining on light alloys and steels, using the pulsed arc, to reduce distortions, and allowing to regulate various working frequencies to obtain more or more penetration of the bath. less accentuated, with sometimes very small beads.

This technique represents one of the most popular methods capable of providing high quality joints, while requiring the work of highly specialized technicians.

Tig welding when to use it:

This joining technique can make use of (selective) filler materials where a consistent coating is required; however, in certain situations, it is possible to proceed without using auxiliary sticks.

This welding process is applicable to various metals including:

- carbon steel;

- stainless steel;

- aluminum;

- magnesium;

- titanium;

- brass;

- copper

- etc…

Tig welding fields of application:

This process has different fields of application: from the repair of molds for plastic materials, for shearing, cold, etc ..., to interventions that require the union of various types of metals including Fe, stainless steel, hardened steels, high-alloy steels , aluminum and its alloys, cast iron, magnesium, titanium, etc ..., to the maintenance of any metal object.

There are no reviews yet.